I thought I would share with you how I make my own small chisels. This is a good way to show that sometimes your tools can be handmade much less expensively than buying them.

Many times you will need a chisel for whatever reason. If you work with historical processes, chisels were used to cut metal before the jewelers’ saw was invented.

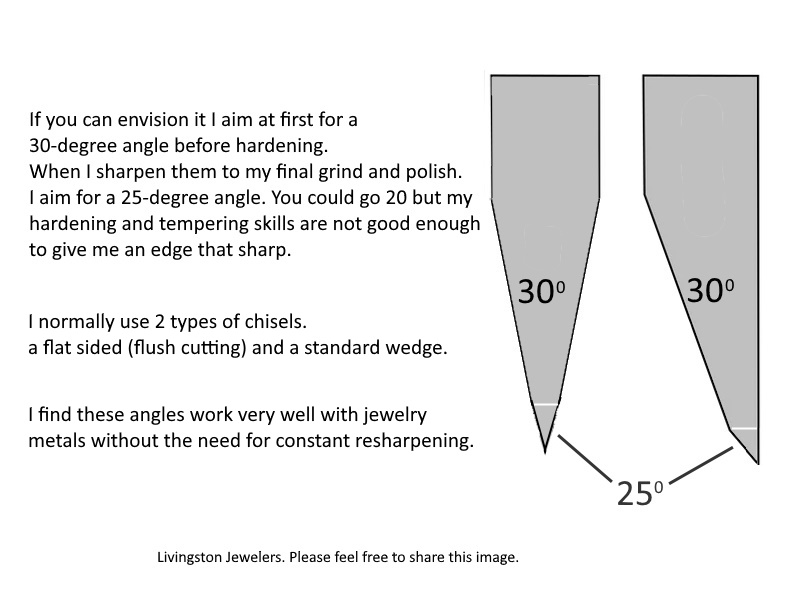

I am also attaching the picture I made showing the angles on my chisels. I edited this to make more sense outside of the conversation I was having.

I do a lot of work in the same manner as many early medieval, medieval, and post-medieval jewelers. So many times I use a chisel to cut metal as jewelers saws would not be invented until some time before they were patented in 1883.

(Link to the patent: https://www.datamp.org/patents/displayPatent.php?pn=284432&id=18629)

Most of my work is done with a recycled chisel from a machinist shop that I ground down and retempered with a very narrow blade. My blade is about 1 mm in thickness and about 2 cm wide. I have the blade ground down to about a 30-degree angle at the cutting tip.

That is my largest chisel. I am the type who would rather make my tools if I can, so my small chisels are made from lengths of piano wire. I did not buy them as finished tools. I started by purchasing several packs of piano wire from McMaster-Carr. I take out a length (12 inches) and cut it to about 3 inches, anneal the metal as it is some REALLY hard stuff. I grind the shape that I want, then give it a rough sharpening, then harden and temper the cutting edge. I then use my graver sharpener to get a really sharp edge.

If you can envision it I aim at first for a 30-degree angle before hardening. When I sharpen them to my final grind and polish. I aim for a 25-degree angle. You could go 20 but my hardening and tempering skills are not good enough to give me an edge that sharp. If you are good at blacksmithing, you could do this as hot-work. I find that about 25 degrees makes a good cutting angle for most jewelry metals and maintains a sharp edge.

all of my small chisels are less than a cm wide and are kept in an old cigar box with paper towels to keep them from rubbing together.

I occasionally need to sharpen them but a quick touch-up on my graver sharpener is all that is usually needed. Be careful. When you are done they should be razor sharp. Do not cut yourself or leave them lying around. Make sure they are put away. (You can ask me why I know this…)

Apologies for the basic nature of the image. I am not a 2D artist.

Also, the different widths of the piano wire make a great set of straight mandrels. I also use the small ones with polished ends as punches to move over bezels and as burnishers.

Only your imagination is the limit of what you can do in making tools.