I am sharing this again as I feel it is a workable way of maintaining inventory in a small working shop. Written a few years ago when gold prices were much lower you can see how this is even more valuable now with metal prices. Wow. I wrote this in April of 2005!

I am not saying this works for all shops but as a lone person doing everything, it helped. the setup took some time but I feel it helped me a lot. I did not have fancy software made specifically for jewelers as I was starting on a shoestring. As I made money from jobs, I paid bills and plowed as much as possible back into the business. I am not good with math either so automating as much as possible helped me as well.

One of the annoying tasks that I had to do every 3 months as a self-employed bench jeweler was inventory so that I could accurately submit my quarterly taxes. As I deal with monetary metals, the values would fluctuate every day so it was tough at first to figure out a way to accurately keep track of the loss and gains in the value of my merchandise. My inventory, without being touched, could fluctuate several thousand dollars over the course of a weekend! And that was at an average for the year of $430 per ounce. With prices as they are today, an accurate value of your inventory is even more important.

Now a huge corporate shop might have plenty of staffing to record the price of every finding in a central warehouse and send items to their shops. But as a single guy who had to take 3 days out of valuable work time every quarter, every minute away from my bench is lost income.

I was always looking for a way to increase efficiency in taking inventory and I seem to have found a way that works and seems to be accurate enough that my State Department of Revenue did not have problems with it.

This takes a little setup but after that first part, I think this will make your life much easier. I have been doing this since the spring of 2005 and I still use this system. I am mostly retired at this point in my life so I only do inventory at the beginning of the year in January.

I used to have to weigh every finding, add up the weights, and hope that I weighed everything correctly. It would take days! Then I had to put everything into Excel so I could see if the value of my business had gone up or down.

I know a lot of jewelers who do a lot of repairs will order metals and findings, and throw them in an old box still in the little plastic zip-lock baggies they came in. It is hard to keep track of what they have, what they need, and what they need to order, so they end up with a lot of duplicates of things they do not need and are always having to order findings that they thought they had in stock. Tax time results in wild guesses and not knowing how healthy their business was.

As part of my daily paperwork, I compiled a database of findings that I regularly use, and as each order comes in, I put everything into Excel to track what I bought and what I paid for it.

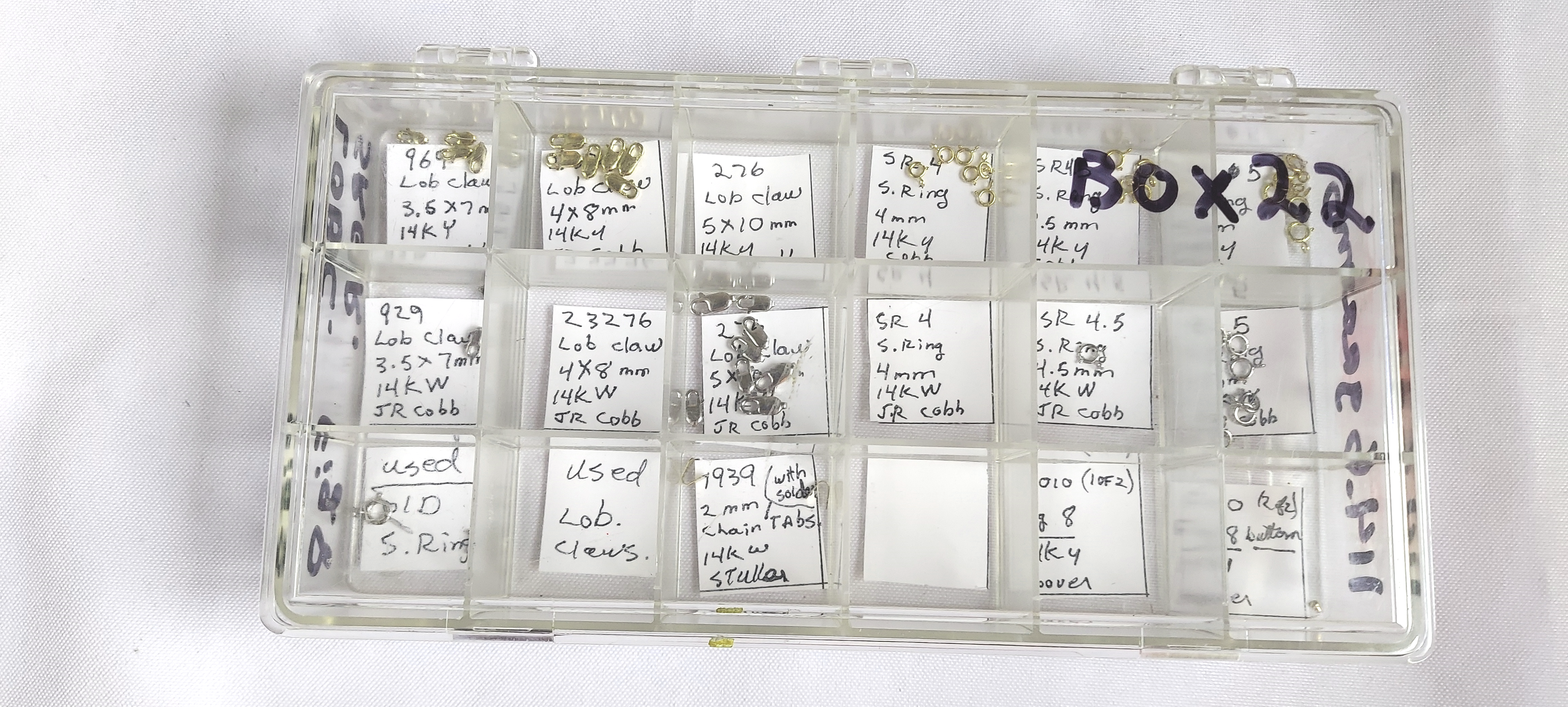

I keep everything in my safe but I want to be able to grab a finding quickly so I can get on with the repairs and custom jobs that I am doing that day. My preferred way of storing findings is to keep them in small plastic organizer boxes with dividers. The size that works best to store in my safe are the 16-bin organizer boxes with a hinged lid.

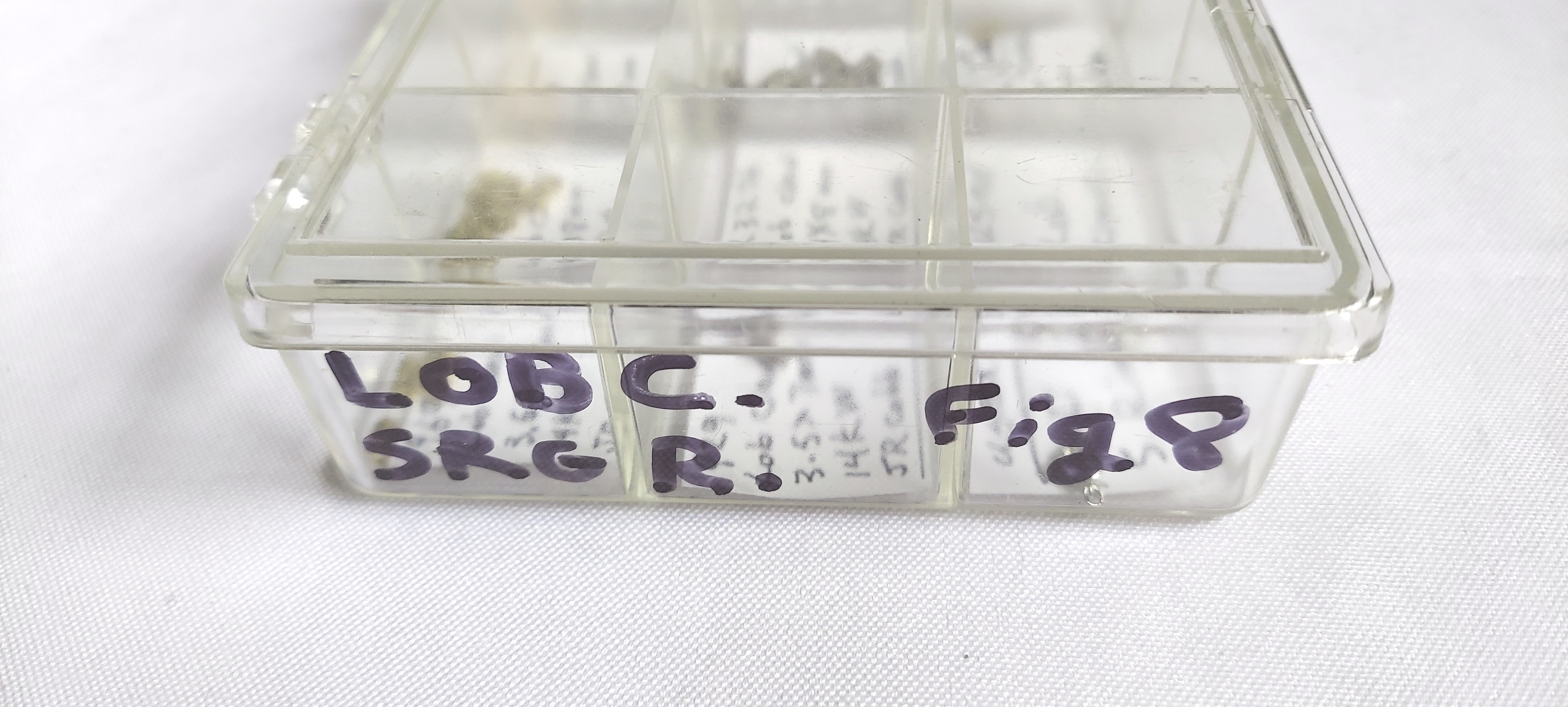

To make things simple, I keep similar items in each numbered box and label the end so I can quickly grab the box I need in an instant. 4 prong heads all in the same box, clasps in the same box, bangle components, etc.

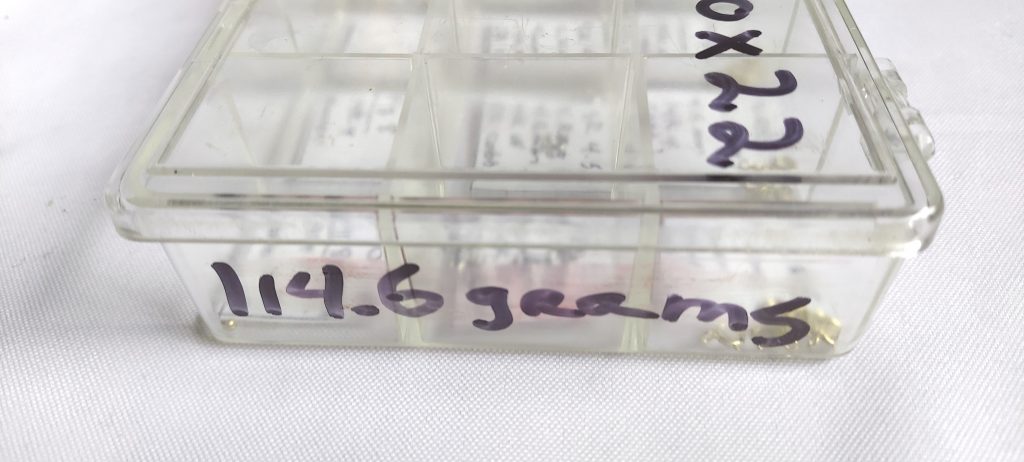

Now this is where I start saving time by being a bit more organized. When I get each new box, I weigh it on my gram scale so I know the exact weight of it when empty.

The box in my picture is labeled box 22, for 14-carat gold Lobster claws, Spring rings, and parts for Figure 8 clasps. It weighs with a small slip of paper in each tray, exactly 114.6 grams.

Each compartment in the organizer boxes will have a different finding and they will be organized by groupings of part numbers or similar styles. As I put each part in, I use the slips to record what is in that bin with the number, name, and other information for the parts in that section of the tray.

Now here is the part that helps during inventory.

Every quarter I record the weight of the findings in every box.

I weigh the box, subtract the weight of the box, and that gives me the weight of the silver, gold, or platinum items in that box. It takes 3 or 4 minutes. I can weigh all of my findings and input them into my Excel sheet in about 3 hours. I still have to open and weigh every finding in all of my job envelopes individually as they are technically still in inventory,

Instead of spending 3 days doing inventory, I can do it in half of a day.

As an example, I will say that in January the weight of this box in January was 200 grams.

Subtract 114.6 grams and that gives me a weight of the findings in that box to be 85.4 grams.

Let’s say that over the next few months, I purchased several dozen lobster claws, spring rings, and a couple of figure-8 clasps to refill the box when it was running low.

Because I used a lot of them, in April the weight of the box is 150 grams.

Subtract the weight of the box again (114.6 grams) and I end up with a weight of 35.4 grams.

I can see with a couple of minutes of work that I have more value in backstock than I did in January in that particular container.

At the time I wrote this up, gold value is about the same now as it was in January (About $430 per ounce). The price of gold means that with the price fluctuating up and down, I paid on average $470 per ounce of gold findings (manufacturing, fabrication, other fees.). This is the value from my average cost in my Excel sheet. For the value that I report to the state, this box is worth $586.56 ($470 times 1.248 ounces).

I do this with each box and I end up with a fairly accurate value of the inventory in my shop and it only took a day instead of 3 days. With 36 boxes to inventory and the findings in my client job bags, this worked well for my small shop.

As a business owner, I would spend about 2 hours out of every 8 doing paperwork and administrative duties. You can set up everything into a database but I am not that skilled so I just put everything into an excel sheet. My Excel sheet has been set up with all applicable findings and corresponding part numbers, descriptions, and page numbers to make ordering simple.

The categories that I use are as follows:

Box #, Position, Stock #, Name, Description, Size, Metal, Vendor, On Hand Quantity. This let me know what I had and who supplied it. A separate sheet was used to record the costs of each item and the shipping to give me a total price per item.

Also a separate sheet where jobs were listed with estimates and actual costs were recorded. I would use this sheet to check off jobs to my accounts to make sure they paid the correct amounts owed.

I also had additional sheets for tools and consumable supplies (not metals and findings) that I used to keep track of things like paper towels, bars of polish, burrs, cratex wheels, large tools such as my ultrasonic, torches, benches, and other things that would be depreciated.

Like I said, a big shop would do more complex accounting but this worked well for me.

I use this system for all of my monetary metals in my shop. Silver, gold, and platinum. I find this makes the process of looking for a finding more efficient and less frustrating, the ordering process will also be more streamlined, and it will be easier to maintain minimum quantities of essential findings thereby reducing job turnaround and increasing profitability for your shop.

Good luck with your own shop.