Follow me on Facebook

Follow me on YouTube

Support me on Patreon

Learning Outcome: I would like you, the viewer, to gain some familiarity with the basics of safety in the jewelry shop as that will help prevent mishaps that can cause pain and injuries. The skill I am hoping to teach you is to be aware of your surroundings and to work safely.

This is a short introduction to safety in the jewelry shop.

Many of the things I will cover in a moment are pretty common-sense points but it is always worth it to remind you of them and some items will be new things you might not have thought of yet.

If you have any questions, please ask in the comments below and I will endeavor to get you the best answer right away.

This will sound scary to some as I am talking about things that can hurt you, but trust me, most of what I will talk about is not going to happen. This falls under “Plan for the worst and hope for the best”. With luck, you will go decades with nothing more serious than a few scrapes and minor cuts.

First, a question to think about:

“Is there a place for safety in the jewelry shop?”

That being said: I tend to think that safety is your responsibility, nobody else’s. If you work for someone else, you don’t expect to be injured. You expect your employer to provide a work environment that is safe and to minimize hazardous work conditions. This is a realistic expectation. everyone I know believes that employers should provide a safe work environment.

Now the corollary to that is that your employer is not the only one responsible for your safety. You are, too. You share accountability to value safe work practices in a positive, proactive way.

If you think a job or a task is unsafe, stop working and report the issue and or fix it. You are responsible to yourself for taking an active role in your safety. If you work for yourself, either as a business or as a hobby, the above statements still apply. Your Safety Is Your Responsibility as you take the position of the employer and the employed at the same time.

Mike Rowe on his blog suggested that Safety is not a thing to be “ranked,” but rather, a state of mind, to be applied as needed to a myriad of situations in varying amounts. But if we were to rank it, it would rarely be “first.” Were safety truly “first,” no level of risk would ever be encouraged or permitted, and no work would ever get done. Or play, for that matter.

https://mikerowe.com/2020/03/walk-me-through-this-safety-third-thing/

To a large degree he is correct. As jewelers you constantly participate in a risk-reward balancing act that is getting the project done without injury.

With “Safety Third”, Mike Rowe was able to start a conversation around occupational safety that continues today, and to acknowledge the unintended consequences of exaggerating the importance of safety on the job. By saying “Safety Third” he reminds us that ultimately, safety is your responsibility, nobody else’s.

So what is the answer to the question earlier “Is there a place for safety in the jewelry shop?”.

The answer is “Yes, there is and it is your responsibility”.

Before starting and sitting down at your bench or workspace look around. Just because everything seems ok at first glance, do not become compliant.

When you become compliant that everything is ok, that is when you tend to have accidents. You are responsible for your own safety at all times so always be aware of what is around you, and how you interact with the environment around your bench.

So how do you make sure you are responsible for your safety? Here is the list of items I think are important for safety in the jewelry shop in no particular order as the points are all important.

Be mentally and physically rested

Physical exhaustion is easy to recognize. After a long day, your hands are tired, your eyes ache from looking at jewelry through an opt-visor, your ass hurts from sitting all day. Rest and maybe a long soak in a tub helps this.

Mental exhaustion is harder to recognize. That’s not a good thing. Physical fatigue can have more to do with mental exhaustion than you think. mental exhaustion will set you back on your heels when your volume of tasks exceeds your capacity to comfortably handle the stress.

Over time, mental exhaustion can lead to burnout, physical issues, and stress-related illness. As soon as you realize why you are feeling so tired, take steps to restore your health, both mental and physical.

Maintaining your personal work area in a clean and orderly manner.

Keep your bench and work area clean. Make it a habit to start the day with a clean bench. At lunch and the end of the day, take 5 minutes to put away your files, put your burrs back into the holder, hang up your pliers, sweep the fool under your bench, and straighten everything. This makes it easier to see if something is out of place or is not right with your work environment.

Wear, maintain and properly store your personal protective equipment (PPE) and make sure you wear it properly.

Eye protection

At a minimum, glasses with side shields. . As you work, bits of material and metals can fly everywhere. Safety glasses are the best but you can purchase small shields that can slip onto the bows of your prescription glasses. This will make it easier to wear an Opti-visor you’re your prescription glasses.

Breathing protection

Make sure you use a face mask. I recommend the paper ones that can be thrown into your recycle bin at the end of the day. You will be surprised how much dust will be on it. All of this did not make it into your lungs.

Hearing protection

Normally this is needed when doing a lot of hammering, chasing and repousse’, raising and sinking a form, and when running loud equipment such as polishing units.

Skin protection

Minimum a set of gloves for working with chemicals. Some chemicals can absorb into the skin and into your blood stream in seconds. Others can burn you or otherwise hurt you. Remember, metal can still be hot enough to burn even if it is not glowing. Vinyl or latex gloves will work when polishing. You can also get a type of fabric tape to wrap your fingers in. just throw this into the recycle when done to reclaim the metal.

Label all chemical containers and become familiar with safety data sheets.

Make sure everything is covered to prevent contamination, spills, and accidental mixing. Label everything, and make sure you keep copies of Safety Data Sheets for everything in your shop. Most sellers of jewelry equipment and tools maintain a webpage where you can download copies of Safety Data Sheets for everything they sell.

Start here on this website for MSDS information: https://www.msdsonline.com/sds-search/

Know evacuation procedures and the location of emergency equipment.

Know where your exits are at all times and make sure they are not blocked.

Fire Extinguisher

Keep by the door of your shop or work space, not near your bench. Mine has never been used. I hope I never need it.

Fire alarms

Preferably a type with a pause button for when you know you will be making some smoke. This turns it off for 5 or 10 minutes. Make sure you change the batteries every 6 months.

Always work with good lighting

Good lights are essential. fluorescent used to be the standard light in shops and on benches. But today, you want LED lights. LED tube lighting can last up to 40,000 hours, are more energy efficient, will save you more money, and will leave less impact on the environment. They also have a high Color Rendering Index (CRI), meaning that these bulbs light up objects in their true and natural color. The light output remains stable throughout the lifetime of the bulb unlike fluorescent that change color as they age.

Always have good ventilation

Always make sure you have good ventilation to pull fumes and smoke from your work area. At the very least a fan that is blowing away from you to pull fumes and particulates away from your face.

Wear only natural fiber clothing

When something gets spilled, or a piece of metal you are heating pops out of a tweezers, or an item gets caught in a buff and thrown, you want these items to not stick to you. Natural fibers do not tend to melt with chemicals, and will slow exposure to them. Also, hot bits of metal tend to fall to the floor. With synthetic fabrics, they tend to stick to you and melt into the fabric causing a burn.

Wear a good comfortable set of closed toe shoes

Murphy’s Law seems to imply that every time you drop something sharp, it will land point down in your toe. (Don’t ask how I know that…) also, hot metal and bits of sharp metal can hurt. So closed toes shoes only. Preferably with leather uppers. Something you can wear for hours without causing foot, leg, or back pain.

Tie back long hair

If you have long hair, tie it back or put it up into a bun. This goes for long beards as well. Reason: rotary tools can grab your hair and yank you into them in less than a second. If you are lucky, you just lose a clump of hair and some scalp. Not so lucky, permanent damage to your neck and spine.

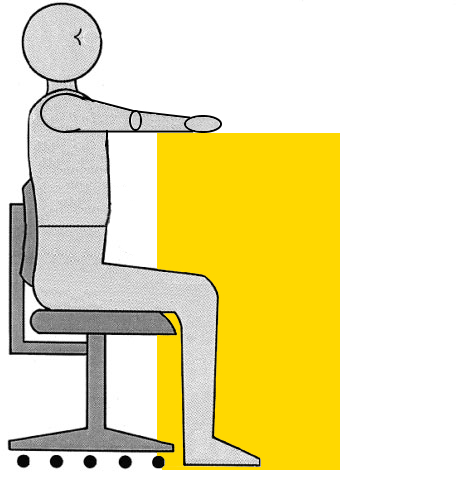

Buy a comfortable chair

This is important as you want to make sure your back is taken care of. I prefer a chair that I can lower or raise a few inches depending on my jobs for the day. As a general rule, you want the tops of your thighs to be horizontal to the ground with your feet flat on the floor. This is a good ergonomic height to sit.

Try to have a good working height for your work surface

If you are working from a kitchen table, you don’t have any control over your working height. My particular preference is “Arm pit height”. When I am sitting in my chair properly (see above), And I hold out my arms, they should rest on the top of my bench. I have added sections of 4X4 blocks under my bench to raise it an additional 3 inches to reach this. What you do will vary on how high your seat is.

This keeps me from bending over my bench and bench pin all of the time. Bending forward can slowly damage the muscles in your neck if you are doing it several hours at a time. If you are prone to migraines like me, you REALLY do not want to be leaning forward. If you can’t control the height of your workspace, make sure you stand up and walk around for at least 5 minutes per hour.

Make sure you have covers on everything

Trash, chemicals, parts, tools. All of these should be covered. It keeps chemicals from being contaminated and spilled, and when you pop a gemstone from tweezers, or drop one and it bounces away, it reduces the number of places you have to look.

Have a spill cleanup kit in your shop

A basic kit will include a roll of paper towels to mop up spills, baking soda to neutralize acidic compounds, and clay kitty litter to soak up liquid spills before they can spread.

Always have a first aid kit in your shop

Do I need to really explain why this is needed? A small one is normally enough, but if you are a klutz like me, get a large one.

Make sure everything is grounded properly

Always use 3 prong plugs and make sure all cords are not damaged. This is not an option. Metallic dust can cause shorts and fires.

Some last reminders: This is making jewelry, you will be working with rotary tools large and small (Dremel / flex-shaft & buffers), files, torches, sharp blades, chemicals, hammers, and heavy steel mandrels & forms.

Some final thoughts…

You will at some point get cut, burned, sliced, and poked. That is just part of how it goes. Most often, it will be just something that a band-aid will cover. It is rare to have a more serious injury, but it does happen. Most accidents happen when you are not watching what you are doing for just a moment.

Look around, and be safe. Safety is your responsibility, nobody else’s.

If you have any questions, feel free to ask them in the comments or email me at glivings@livingstonjewelers.com