Not only is it important to store your jewelry materials in such a way that they are protected, but it is also important to store your tools safely as well. and this includes your consumable items. I am going to share an inexpensive, but valuable way to save labor due to needing to repolish items.

The reason I do it this way is due to having a bad experience a few years ago. I had just finished sanding a raising hammer face with 1000 grit paper and had just wiped it down with a clean cloth, and started with 1200 grit.

After a few seconds, I looked at the hammer face to discover several large scratches.

It seems that some grit from a coarse grit of sandpaper had fallen in between my sheets of 1200-grit paper and had become embedded enough to stick. It only took a few moments to ruin my polish on the hammer face.

It took a bit of thinking but I found the answer was easy.

Just keep the grits separate.

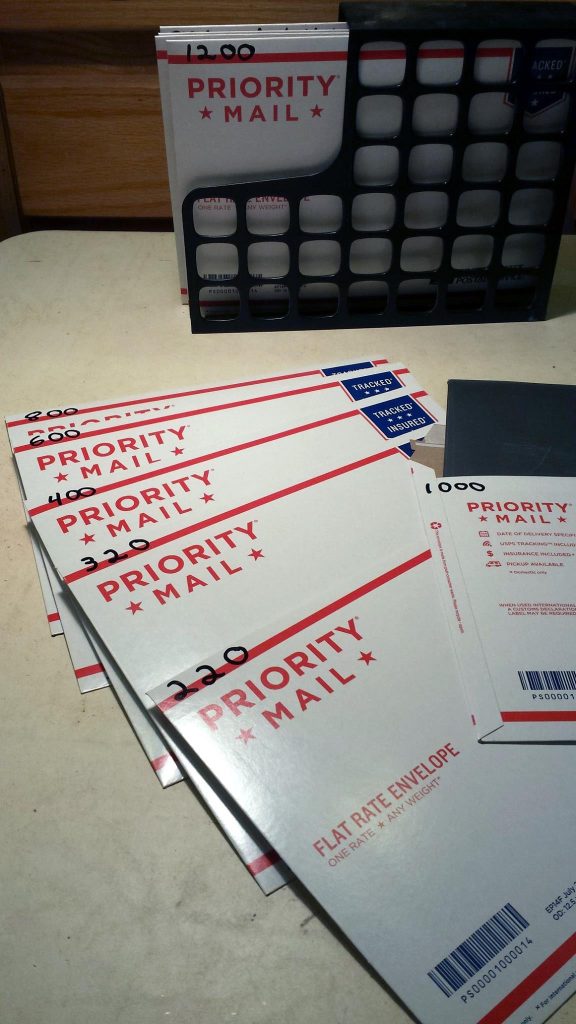

It was such a simple idea that I am embarrassed that I had not thought of it before. I just had to find envelopes that were the correct size to hold. Most of the sheets of sandpaper I purchase are 9 by 11 inches (23 by 28 cm), so they fit very well into Priority Mail Envelopes from the USPS. I did ask for a dozen of these. The guy at the post office said it was ok. So ask first for them. Be nice.

So now I keep my paper in the priority mail envelopes from the post office. Each one holds several sheets and folds over to keep them clean. I remove the cover for the sealing strip on each one and cover that with a single length of masking tape. They all store very nicely in a plastic magazine holder that sits up out of the way on a shelf until I need some. I pull out a sheet, cut off a piece the right size, and put the rest away.

Since then I have not had a single problem with contamination.

The sandpaper grits I use in my jewelry shop are 120, 220, 320, 400, 600, 800, 1000, 1200, 1500, and Crocus (Depending on who you ask, this is also called rouge cloth (about 2000 grit.).

I do not put used sandpaper back in with the new. I have a separate folder for those grouped together. I figure that these used sheets are only good enough for a rough start on new projects. And I do not want to carry old grits from other papers back into the folders with the new sheets.

We all have different ways of organizing. Let me know what you do and what works in your shop.