Saws, Saw Blades and Sawing

In jewelry, you may cut metal one of three ways; with a saw, shears, or a chisel.

- Shears are easy and fast, but they can deform the edge of the metal as they cut. These have been used for at least 1,000 years.

- Chisels are slow and if working with thin metal, tends to deform the edges quite a bit. And a chisel takes a lot of practice to use without errors. These have been used for as long as there has been people making jewelry.

- Since the mid to late 19th century, the choice of jewelers is the modern jewelers saw.

Information about jeweler saw blades

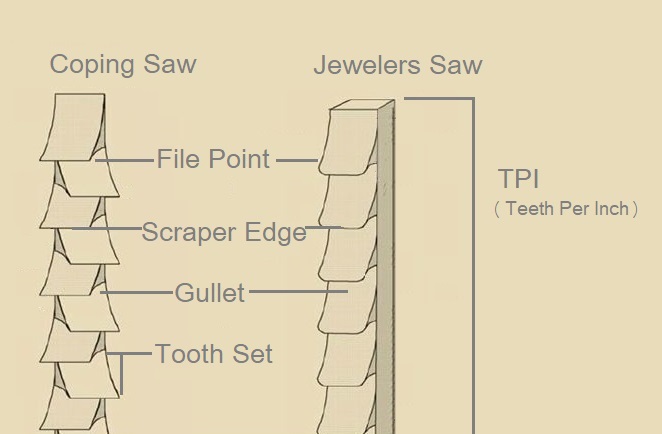

I want to start with some basic information about saw blades. First off, while coping saws and jewelers saw look alike, they are very different. Coping saws are used for wood, and jewelers saws for metal.The materials dictate the design of the blade. Coping saws are purchased using TPI (teeth per inch) You can get them from 10 TPI for a course blade, down to a very fine 32 TPI. (I am not a woodworker so if I am wrong in this, please let me know and I will update the information.)

Jewelers blades are sized differently from coping saw blades. They range from a size 6 down to 0, then smaller from 1/0 down to 10/0. these go from fairly thick down to as fine as a hair! But still much smaller than a coping saw.

- Coping saw

- a saw with a very narrow blade stretched across a U-shaped frame, used for cutting curves in wood.a coping saw holds the blade in tension in a metal frame.

- Jewelers saw

- A jeweler's saw, also known as a piercing saw, is a type of saw commonly used in jewelry making on sheet metal. It is usually used on softer metals as the saw blades are delicate. Like a coping saw, a jewelers saw holds the blade in tension in a metal frame.

- TPI (teeth per inch)

- How many teeth are on the saw blade in one inch. The number of teeth per inch (TPI), along with gullet size, width and depth of the space between the teeth determines the material the blade can cut. Blades with a low TPI deliver faster cuts with rougher edges. The finer the TPI, the finer and slower the cut.

- Tooth set

- The angle of the teeth relative to the plane of the blade is called the set. A blade with a more pronounced set will cut more aggressively, but it will also consume more material because the kerf (the slot cut by the blade) will be wider. This can be an issue if you're trying to conserve material on very expensive stock. I am unsure if this is done on smaller jewelers blades, but I have run into this on only size 4 and 6 jewelers blades. A large tooth set is important for wood as much more material is removed with each pass of the saw blade.

- File point

- The edge of the scraper. This defines the width of the kerf.

- Scraper edge

- This is the edge that scrapes off the material being sawn. Think of this as the blade of a very small chisel.

- Gullet

- This is the space behind each saw tooth. This space helps carry the waste materials out of the cut and as the blade exits, this material falls free leaving the saw tooth ready to cut again. When the gullets are deeper, the chiseling action of the teeth is more aggressive.

How saws cut

Each tooth on a saw blade is essentially a tiny, sharp chisel that gouges out material as it passes through a workpiece. Typically, the more teeth a saw blade has, the smoother the cut will be. These smooth cuts come at the price of speed since blades with many teeth achieve their fine finish by removing material more slowly. Saw blades with fewer teeth will cut faster and more aggressively, but generally produce somewhat rougher finishes.

Note About Jeweler’s Saw Blade Sizing

Jeweler’s saw blades are sized on a scale.

- Consider size 0 (zero) to be the middle of the scale

- Larger blades are subsequently numbered: #1, #2, #3 etc. The higher the number, the larger the blade.

- Smaller blades are subsequently numbered: 1/0, 2/0, 3/0. The higher the number the smaller the blade.

Choose the blade that best suits the thickness of the material being cut. The ideal ratio is 2.5 to 3 teeth on the material at any time. Now I would also caution against listening too close to others when they say you MUST use a particular size blade on a certain thickness of metal. Depending on your job, and your personal taste, you may use a different blade size than others.

As long as you have at least 2.5 to 3 teeth on the metal, you can use whatever blade you would like. This keeps the metal from getting in between the saw teeth and catching in the blade gullet. That leads to many, many blades changes and a frustrating day. Use the chart below to find the saw blade you need.

Also. Remember to use some sort of blade lubricant! You can purchase commercial lubricants, or use beeswax. Find one you like and stick with it.

Use the chart below to find the saw blade you need.

| Blade Size | For use with: | MM thickness | Blade Thickness | Blade Depth | Teeth per Inch | Drill Size for Piercing |

|---|---|---|---|---|---|---|

| 6 | 6-8 gauge | 4.11mm to 3.26mm | .0173'' | .0370'' | 33.0 | 58 |

| 5 | 8 gauge | 3.26mm | .0158'' | .0331'' | 35.5 | 65 |

| 4 | 10 gauge | 2.58mm | .0150'' | .0307'' | 38.0 | 67 |

| 3 | 12-14 gauge | 2.05mm to 1.62mm | .0140'' | .0290'' | 40.5 | 68 |

| 2 | 16-18 gauge | 1.29mm to 1.02mm | .0134'' | .0276'' | 43.0 | 70 |

| 1 | 18-20 gauge | 1.02mm to 0.81mm | .0120'' | .0240'' | 51.0 | 71 |

| 1/0 | 18-22 gauge | 1.024mm to 0.644mm | .0110'' | .0220'' | 53.5 | 73 |

| 2/0 | 20-22 gauge | 0.812mm to 0.644mm | .0103'' | .0204'' | 56.0 | 75 |

| 3/0 | 22 gauge | 0.644mm | .0095'' | .0190'' | 61.0 | 76 |

| 4/0 | 22 gauge | 0.644mm | .0086'' | .0175'' | 66.0 | 77 |

| 5/0 | 22-24 gauge | 0.644mm to 0.511mm | .0080'' | .0157'' | 71.0 | 78 |

| 6/0 | 24 gauge | 0.511mm | .0070'' | .0140'' | 76.0 | 79 |